Equipment & Services

-

Weinig Moulder Technology

-

Charley Robot CNC Template Cutter

-

Newman-Whitney Helical Head Planer

-

Surfaced Two-Sides (S2S)

-

S4S - Square or Eased Edges

-

Ripped Two-Edge (R2E)

-

Straight Line One-Edge (SL1E)

-

Precision Double-End Trimming

-

Resawing & Custom Knife Grinding

-

Paint-Ready Priming/Staining

-

Custom Flooring & Butcher Blocks

-

Stair Treads & Risers

-

Over 2500 Custom Profiles

-

Value Consulting & Engineering

-

Same-Day Quoting

Millwork

Since 1976, Continental Hardwood has provided custom machining and moulding for both hardwood and softwood lumber.

We utilize state-of-the-art moulders, rip saws, planers, and sanding equipment to produce mouldings and millwork

which meet the strictest quality standards.

Our cabinet and furniture components are closely monitored throughout the entire production process. From species, grade,

and profile selection, to tolerance monitoring, our experienced staff always strives to exceed your expectations.

Our fleet of trucks deliver Continental Hardwood's fine architectural millwork and lumber products on a daily basis to cabinet

manufacturers, furniture makers, casework fabricators, and general contractors throughout the Pacific Northwest.

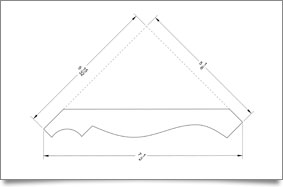

1. Drawing Selection

The production process begins with a custom drawing submitted by you, or chosen from our extensive catalog of existing profiles.

2. Template Creation

Using advanced software, and our state-of-the-art robotic template cutter, we generate a plastic profile template based on your selected drawing.

3. Knife Grinding

After completing your profile template, we grind the high-speed steel knives for cutting. Each knife must meet our stringent quality standards before use.

4. Moulder Run

Once the heads are production-ready, we use them with our Weinig moulder to machine raw lumber at close tolerances into your desired components.